Fire Door Inspections- What are we learning?

As published in DHI’s Door Security + Safety magazine – December 2018

With obtaining several years of invaluable experience in performing annual NFPA 80 inspections of fire rated doors, our company has identified several key lessons-learned that we thought would be a valuable resource for door and facility professionals to consider.

With obtaining several years of invaluable experience in performing annual NFPA 80 inspections of fire rated doors, our company has identified several key lessons-learned that we thought would be a valuable resource for door and facility professionals to consider.

Lesson 1

Fire protection door openings in the occupancies we began performing work in were in much worse condition than initially expected. For example, one facility that our staff surveyed last year assured us ‘we would not find one deficiency in their facility.’ Their best maintenance technician had thoroughly gone through all the doors and signed off that they were 100% compliant. We inspected 98 doors and of that total number 97 failed the NFPA 80 inspection requirements. Was the technician lousy at his job? Not at all – rather he was a fantastic door technician. What was missing was a proper understanding of the applicable code requirements. This high rate of failure has been noted at the majority of facilities following initial annual inspections.

Lesson 2

We had the expectation that overall door code-compliance would naturally increase with subsequent annual inspections. While rates did rise, they were not anywhere close to where they were expected to be. Completing repairs to bring the doors into compliance did not guarantee future compliance. Doors are a living part of a building in the sense that every day the components are moving, flexing and being stressed. As hardware reaches the end of its life cycle, inspections accordingly note that things break. Doors, particularly in heavily traveled portions of the building have increased stress due to occupant use, and at times abuse – in healthcare occupancies where many of our inspections occur, carts, beds and equipment take a heavy toll on fire doors and frames. While occupants and user groups in a facility consider it ‘just another door’, as professionals we recognize that the door must be ready to serve as a fire barrier when called upon, and it is imperative to recognize the irreplaceable human lives that are depending on these doors to properly function as required by code.

Lesson 3

We have also realized that research into various code application requirements, beyond just NFPA 80 is often necessary. It is thus imperative to seek out competent expertise in building, fire and life safety codes and standards to assist inspectors in applying the appropriate requirements – this may be through a trusted regulatory authority such as a fire or building official or other code consultant.

We would like to highlight some issues we have encountered in the course of annual inspections so as to help highlight some of the complexities of this process:

- Does the door have a label? Yes, but did we read it?

- What is the barrier rating on the life safety plan? Is it the correct door?

- A 20-minute door in a 2-hour barrier wall is incorrect – which is likely obvious. How about a 45-minute door in a 1-hour barrier surrounding a medical gas storage room? A 60-minute door would be required. At times an inspector needs knowledge of codes beyond NFPA 80 to understand the correct application.

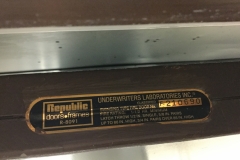

- What is the required latch throw? (see picture #1)

- This label has several qualifications if installed in pairs. Is the correct latch bolt installed?

- Where is the door located? (see picture #2)

- The label calls for installation in single swing locations only. This label was found on a pair of double egress doors thus voiding the label.

- Is a gasket required if there is an ‘S’ on the label? (see picture #3)

- It’s not automatic. Only if required by the life safety, fire or building code.

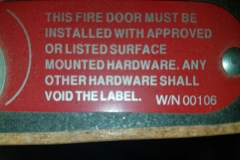

- Is the correct hardware installed? (see picture #4)

- Sometimes it is noted that cylinder handle-sets are installed on doors labeled for use only with surface mounted hardware. The reverse has also been observed, doors with exit hardware that were not labeled for such.

- What is the barrier rating on the life safety plan? Is it the correct door?

- Is the hardware installed correctly?

- What does the manufacturer require? (see picture #5)

- Even though the inside of a 90-minute door looks like drywall, plastic anchors are not approved to install exit hardware. Often it is noted that drywall screws or #8 zip screws are holding on hardware where #12 or ¼” through bolts are required.

- Why all the empty fastener locations? (see picture #6)

- All the required fasteners must be installed. This strike begs a few more questions: The Von Duprin 499F strike is specified when surface vertical rod hardware is installed less bottom rod and necessitates that there is a second part that is installed above the top latch on the door. With it being missing, additional questions are subsequently raised, such as whether there is a fire pin installed, or not? If this is a modification to existing hardware? Does the hardware manufacturer allow the modification? Does the door manufacturer? Have you kept any documentation to show the AHJ that it is an approved modification?

- How should it be installed? (see picture #7)

- This is an access door in a 2-hour shaft. The four 1-1/4” drywall screws that ‘anchored’ this door were not into any framing! Caulk was literally all that held this door in place. Also notice the huge gap in the drywall around the door frame. This installation failed.

- What does the manufacturer require? (see picture #5)

- Is this an approved modification?

- Can a double acting door be converted? (see picture #8)

- Welded steel angle was added to make a stop. In addition, the doors had terrible clearance issues due to the rounded edges of double acting doors. Is this acceptable? The real question is, how was the door and frame tested and can it be proved that the doors will survive for the required fire endurance?

- Can we extend a door with a non-compliant bottom clearance? (see picture #9)

- A small piece of wood was attached to the bottom of the door. It was hard to spot due to a kick-plate and mop-plate installed on either side of the door covering the extra piece of wood. This is not an approved repair.

- Can we field modify a frame for electrified hardware? (see picture #10)

- This frame was modified for an electric strike, then had the strike removed. It really shows why field-modification to a frame for this type of hardware is not advisable and will likely not be accepted by the manufacturer. This frame has been severely weakened by the modification.

- Can we add parts to make it work? (see pictures 11, 12, 13 and 14)

- The adage, ‘necessity is the mother of invention’ certainly holds true in door repair, and nowhere does this seem to be truer than in the installation of magnetic hold-open devices. They are obviously not compliant solutions, but one has to appreciate the ingenuity.

- Can we add extra fasteners? (see picture 15)

- One can almost hear the installer saying, ‘I’m going to get one of these screws to grab something.’ Again, the question becomes has this hinge been tested this way? Also, has the door been damaged beyond use? Drilling 8 holes in the hinge stile would severely compromise its st

- Need a new lock?(see picture 16)

- Remove the mortise lock, install an edge guard and new cylinder lock. As one of my instructors at DHI would say, ‘This results in a pile of fire wood.’ This type of modification voids the door label.

- Can a double acting door be converted? (see picture #8)

- Is this an approved application?

- Can an edge guard fix a clearance problem? (see picture 17)

- We have seen door edge guards installed to solve clearance issues. While not listed to solve clearance issues, it may be a solution for a small clearance issue (ask your AHJ). A couple questions though… Is it rated for use on a fire door? Is it installed per the manufacturer’s instructions? Meaning, we cannot add additional shims behind the edge guard to close a larger clearance issue. The final question has to do with the picture. Does the installation of the edge guard affect how far the latch engages the strike? Clearance issues are not just about how much smoke will get past. It is also about whether or not the latch bolt will stay engaged during a fire. If you have ever seen a video of a fire door test (SDI has one on YouTube) you will realize that the doors pull, bow and twist. If the latch bolt is not long enough, it will allow the door to pop open during a fire.

- Its stainless steel, can it be used? (see picture 18)

- This is a beautiful frame protector. Is it rated for use on a fire door?

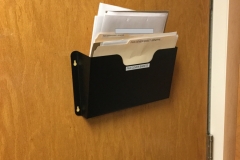

- What can I install on my door? (see pic 19 and 20)

- We see this often. A mailbox is needed. A coat hook is needed. Some protection for the hardware is needed. We would need to find a product that is rated for use on a fire door.

- Creativity at its best. (see picture 21)

- This one always makes me smile. Creative, yes. Compliant, no.

- Can an edge guard fix a clearance problem? (see picture 17)

- Is it damaged beyond use?

- How to repair a large hole in the frame? (see picture 22)

- We see this often. A magnetic lock is removed leaving behind a large hole in the frame. How would you repair this?

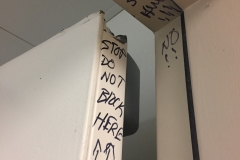

- I must hold this door open. (see picture 23)

- I sense a battle between the janitors and the maintenance staff. Have the welds broken in the door? Have the clearances been affected? Have the hinge pockets been over stressed and bent or broken?

- Looks like a beautiful installation. (see picture 24)

- Due to some clearance issues our technician had to remove the hinge. That’s when we found out that the hinge pocket was broken, and the edge guard was all that was ‘holding’ the door together. We have to ensure that any repairs we do will survive a fire and the only way to do that is to test it. We need to know when to say, ‘replace it’.

- Can I reuse a door we have in storage? (see picture 25 and 26)

- While it is completely acceptable to reuse doors in good condition, we need to make sure all the hardware on the door will match the existing frame conditions. These types of modifications are not permitted.

- What to do with a rusted frame? (see picture 27)

- Obviously, this frame will need to be replaced due to rust damage. My real question is what are they cleaning the floors with?

- How to repair a large hole in the frame? (see picture 22)

The inspectors at our company had a good time putting these examples together. It is a real testament to the creativity of the maintenance staff at these facilities. While some of these repairs would be just fine on a non-rated door, they will cause problems on a fire protection rated door opening. Compliant fire doors are a huge part of our facilities fire protection. If just one door does not perform as specified, many lives could be put at risk, and as such it is critical that we do all we can to make sure our fire doors are ready to do their job.

We can truly see the wisdom in this new code requirement for annual inspections. While in the beginning we may have chafed or balked at the thought of this new requirement, our compliance rates are showing that we needed to do better.

I hope these examples help highlight that an effective inspection really requires three components: 1. Thorough knowledge of the code and how it applies to your facility, 2. Thorough knowledge of proper installation and application of hardware on rated doors and frames, and 3. The ability to effectively communicate what the deficiencies are and what possible solutions there may be. If you find that your facility could use help with inspections, find one of the many DHI trained and certified FDAI’s (Fire & Egress Door Assembly Inspector). Their experience and knowledge will be an invaluable resource for you.

-Mark Waller, FDAI I Managing Director of AEGIS